About machine

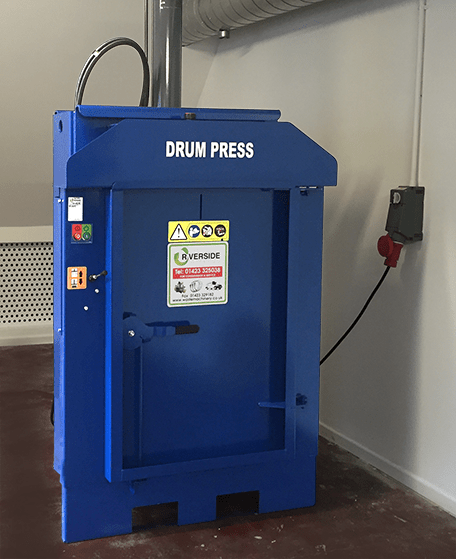

This compact drum press may be a neat waste handling solution, suitable for indoor or outdoor use. But packed into this tidy hydraulic equipment is a 24 tonne compaction force that can crush light steel drums or rolling hoop barrels of up to 205 litres. Designed to revolutionise your approach to waste handling, this drum press even collects residual fluids discharged during compaction. The 30 litre collection tank can simply be drained through an integral tap, when full. This technology has been engineered to reduce organisations’ waste management costs and storage constraints. Suitable for businesses of all types and sizes, the drum press is available to purchase or rent, ensuring an affordable waste machinery solution whatever your cash flow or capital availability.

Did you know..?

The drum press can also be modified to crush materials such as plastic pales, within a 205l drum or barrel – perfect for when waste collections are charged according to volume, not weight! Find out more…

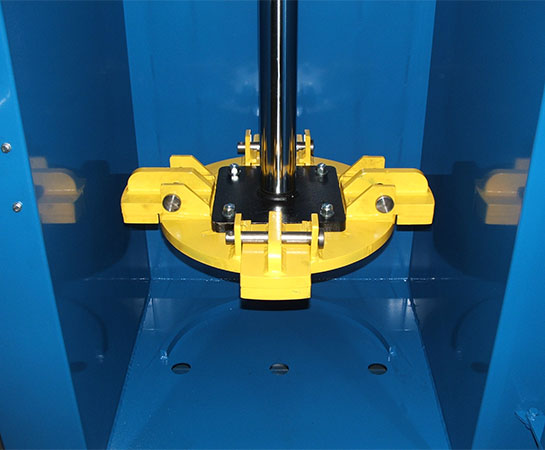

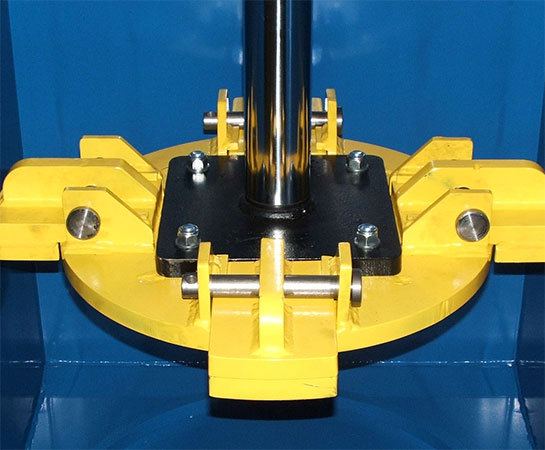

PLUS: Talk to us about our multi-head press accessory, ideal for clients wanting to alternate between pressing materials inside a drum and crushing the drums themselves.

Spec

• Press Force – 24 Tonnes

• Cycle Time – 40 seconds

• Noise Level – 75 decibels

• Machine weight – 690 kg

• Power Supply 32 amp 3 phase 11kW-400V-50Hz

• Overall Dimensions (H x W x D) – 2463 x 1140 x 1000mm

• Optional Transportation Height – 1800mm

• Compaction Ratio – 10:1

Key Features

• 12-month warranty

• 24 Tonne press force

• Suitable for up to 210L barrels

• 30-litre residual liquid collection tray with tap connection

• Clear controls for easy operation

• Totally enclosed shell ensures a high level of safety

• Can be sited outside

• 32amp 3 phase electrics

• CE approved

• Powder coated finish for durability